The feasibility of fabricated 3D-printed immobilization masks for radiotherapy: mechanical and dosimetric analysis

Main Article Content

Abstract

Background: 3D printing technology is becoming widely popular in the medical field, particularly in radiotherapy, where it is used to fabricate immobilization masks from thermoplastic materials because it can generate geometric figures and produce sophisticated templates eligible for individual patients.

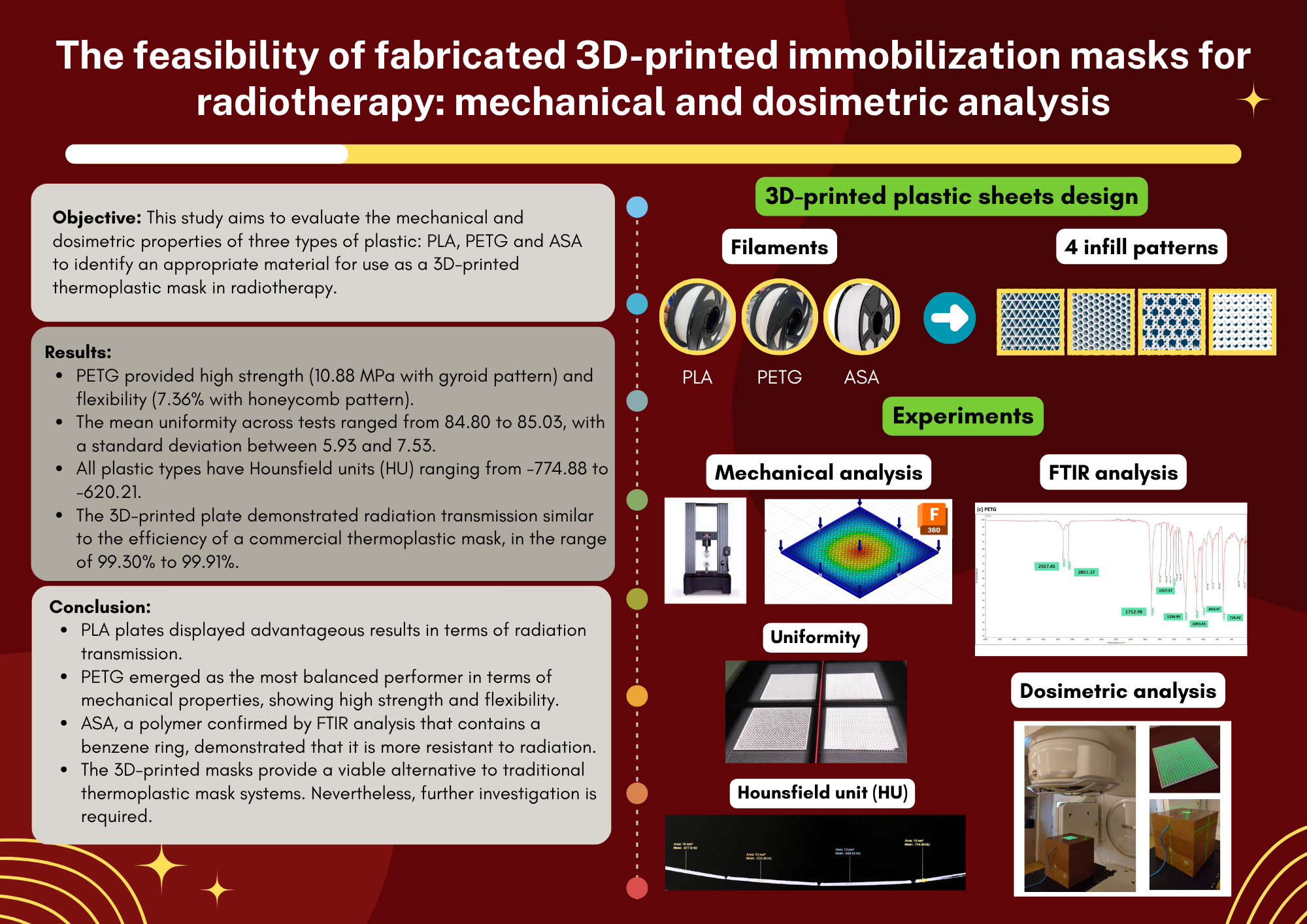

Objectives: This study aims to evaluate the mechanical and dosimetric properties of three types of plastic: polylactic acid (PLA), polyethylene terephthalate glycolmodified (PETG), and acrylonitrile styrene acrylate (ASA) to identify an appropriate material for use as a 3D-printed thermoplastic mask in radiotherapy.

Materials and methods: The 3D-printed square plastic samples were designed with four infill patterns: triangle, honeycomb, gyroid, and honeycomb-gyroid, and were manufactured using fused deposition modeling (FDM) 3D printing technology. This study analyzed the characteristics regarding mechanics, uniformity, and radiation transmission.

Results: Mechanical testing demonstrated that PETG provided high strength (10.88 MPa with gyroid pattern) and flexibility (7.36% with honeycomb pattern). The mean uniformity across tests ranged from 84.80 to 85.03, with a standard deviation between 5.93 and 7.53. All plastic types have Hounsfield units (HU) ranging from -774.88 to -620.21. The 3D-printed plate demonstrated radiation transmission like the efficiency of a commercial thermoplastic mask, in the range of 99.30% to 99.91%.

Conclusion: All three types of plastic have proven to be appropriate alternative materials for the integration of an immobilization mask. PLA plates displayed advantageous results in terms of radiation transmission, while PETG emerged as the most balanced performer in terms of mechanical properties, showing high strength and flexibility. ASA, a polymer confirmed by FTIR analysis that contains a benzene ring, demonstrated that it is more resistant to radiation. The 3D-printed masks provide a viable alternative to traditional thermoplastic mask systems. Nevertheless, further investigation is required.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Personal views expressed by the contributors in their articles are not necessarily those of the Journal of Associated Medical Sciences, Faculty of Associated Medical Sciences, Chiang Mai University.

References

Duarte J, Loja MAR, Portal R, Vieira L. 3D printing of abdominal immobilization masks for therapeutics: dosimetric, mechanical and financial analysis. Bioengineering (Basel). 2022; 9(2): 55. doi: 10.3390/bioengineering9020055.

Mattke M, Rath D, Häfner M, Unterhinninghofen R, Sterzing F, Debus J, et al. Individual 3D-printed fixation masks for radiotherapy: first clinical experiences. Int J Comput Assist Radiol Surg. 2021; 16(6): 1043-9. doi: 10.1007/s11548-021-02393-2.

Sa’ude N, Ab Latib NAN. A study on the mechanical properties of PLA, ABS and PETG filament printed by various type of infill design using 3D printing machine. RPMME. 2023; 4(2): 162-7. [cited 2025 May 11]. Available from: https://publisher.uthm.edu.my/periodicals/index.php/rpmme/article/view/11492.

Asfia A, Novak JI, Mohammed MI, Rolfe B, Kron T. A review of 3D printed patient specific immobilisation devices in radiotherapy. Phys Imaging Radiat Oncol. 2020; 13: 30-5. doi: 10.1016/j.phro.2020.03.003.

Farah S, Anderson DG, Langer R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv Drug Deliv Rev. 2016; 107: 367-92. doi: 10.1016/j.addr.2016.06.012.

Van der Walt M, Crabtree T, Albantow C. PLA as a suitable 3D printing thermoplastic for use in external beam radiotherapy. Australas Phys Eng Sci Med. 2019; 42: 1165-76. doi: 10.1007/s13246-019-00818-6.

Ramírez-Revilla S, Camacho-Valencia D, Gonzales- Condori EG, Márquez G. Evaluation and comparison of the degradability and compressive and tensile properties of 3D printing polymeric materials: PLA, PETG, PC, and ASA. MRS Commun. 2023; 13(1): 55-62. doi: 10.1557/s43579-022-00311-4.

Robar JL, Kammerzell B, Hulick K, Kaiser P, Young C, Verzwyvelt V, et al. Novel multi jet fusion 3D-printed patient immobilization for radiation therapy. J Appl Clin Med Phys. 2022; 23(11): e13773. doi: 10.1002/acm2.13773.

Novak JI, Liu MZ-E, Loy J. Designing thin 2.5 D parts optimized for fused deposition modeling. Additive Manufacturing Technologies From an Optimization Perspective. Hershey, PA: IGI Global; 2019: pp 134-64. doi: 10.4018/978-1-5225-9167-2.

Kim T-H, Cho M-S, Shin D-S, Shin DH, Kim S. Development of a real-time thermoplastic mask compression force monitoring system using capacitive force sensor. Front Robot AI. 2022; 9: 778594. doi: 10.3389/frobt.2022.778594.

Demir E, Duygun İK, Bedeloğlu A. The mechanical properties of 3D-printed polylactic acid/polyethylene terephthalate glycol multi-material structures manufactured by material extrusion. 3D Print Addit Manuf. 2024; 11(1): 197-206. doi: 10.1089/3dp.2021.0321.

Zhang Y, Zhang X, Cao Y, Feng J, Yang W. Acrylonitrilestyrene‐acrylate particles with different microstructure for improving the toughness of poly (styrene‐coacrylonitrile) resin. Adv Polym Technol. 2021; 2021(1): 3004824. doi: 10.1155/2021/3004824.

Moghaddam SHZ. Applications of Three-Dimensional Printing Technology in Radiotherapy: Advances in 3D Printing. London: IntechOpen; 2023. doi: 10.5772/intechopen.109398.

Alssabbagh M, Abdulmanap M, Zainon R. Evaluation of 3D printing materials for fabrication of a novel multifunctional 3D thyroid phantom for medical dosimetry and image quality. Radiat Phys Chem. 2017; 135: 106-12. doi: 10.1016/j.radphyschem.2017.02.009.

Zhao Y, Moran K, Yewondwossen M, Allan J, Clarke S, Rajaraman M, et al. Clinical applications of 3-dimensional printing in radiation therapy. Med Dosim. 2017; 42(2): 150-5. doi: 10.1016/j.meddos. 2017.03.001.

Moldovan A, Cuc S, Prodan D, Rusu M, Popa D, Taut AC, et al. Development and characterization of polylactic acid (PLA)-based nanocomposites used for food packaging. Polymers (Basel). 2023; 15(13): 2855. doi: 10.3390/polym15132855.

Talataisong W, Ismaeel R, Marques TH, Abokhamis Mousavi S, Beresna M, Gouveia M, et al. Mid-IR Hollow-core microstructured fiber drawn from a 3D printed PETG preform. Sci Rep. 2018; 8(1): 8113. doi: 10.1038/s41598-018-26561-8.

Haefner M, Giesel F, Mattke M. 3D-Printed masks as a new approach for immobilization in radiotherapy-A study of positioning accuracy. Oncotarget. 2018; 9(5): 6490-8. doi: 10.18632/oncotarget.24032.

Aboelella MG, Ebeid SJ, Sayed MM. Layer combination of similar infill patterns on the tensile and compression behavior of 3D printed PLA. Sci Rep. 2025; 15(1): 11759. doi: 10.1038/s41598-025-94446-8.

Dawood LL, AlAmeen ES. Influence of infill patterns and densities on the fatigue performance and fracture behavior of 3D-printed carbon fiber-reinforced PLA composites. AIMS Mater Sci. 2024; 11(5): 833–57. doi: 10.3934/matersci.2024041.

Pandžić A, Hodžić D, Milovanović A, editors. Effect of infill type and density on tensile properties of PLA material for FDM process. Proceedings of the 30th DAAAM international symposium; 2019: 0545-0554. doi: 10.2507/30th.daaam.proceedings.074.

Pandzic A, Hodzic D, editors. Mechanical properties comparison of PLA, tough PLA and PC 3D printed materials with infill structure–Influence of infill pattern on tensile mechanical properties. IOP Conf Ser Mater Sci Eng. 2021; 1208 (1): 012019. doi: 10.1088/1757-899X/1208/1/012019.

Amador AMG, Avendano RAV, González AQ, Fernández LP. Mechanical characterization and testing of multi-polymer combinations in 3D printing. Heliyon. 2025; 11(3): e42420. doi: 10.1016/j.heliyon. 2025.e42420.

Eryildiz M. The effects of infill patterns on the mechanical properties of 3D printed PLA parts fabricated by FDM. Ukr. J Mech Eng Mater Sci. 2021; 7(1-2): 1-8. doi: 10.23939/ujmems2021.01-02.001.

Sedlak J, Joska Z, Jansky J, Zouhar J, Kolomy S, Slany M, et al. Analysis of the mechanical properties of 3D-printed plastic samples subjected to selected degradation effects. Materials (Basel). 2023; 16(8): 3268. doi: 10.3390/ma16083268.

Cressall S, Phillips CO, Al-Shatty W, Deganello D. The effect of high-intensity gamma radiation on PETG and ASA polymer-based fused deposition modelled 3D printed parts. J Mater Sci. 2024; 59(4): 1768-82. doi: 10.1007/s10853-023-09309-2.

Iacob DV, Zisopol DG, Minescu M. Technicaleconomical study on the optimization of FDM parameters for the manufacture of PETG and ASA parts. Polymers (Basel). 2024; 16(16): 2260. doi: 10.3390/polym16162260.

Asfia A, Deepak B, Novak JI, Rolfe B, Kron T. Multi‐jet fusion for additive manufacturing of radiotherapy immobilization devices: Effects of color, thickness, and orientation on surface dose and tensile strength. J Appl Clin Med Phys. 2022; 23(4): e13548. doi: 10.1002/acm2.13548.

Kalender WA. Computed tomography: fundamentals, system technology, image quality, applications: 3rd Edition. Germany: John Wiley & Sons; 2011.

Park S-Y, Choi N, Choi BG, Lee DM, Jang NY. Radiological characteristics of materials used in 3-dimensional printing with various infill densities. Prog Med Phys. 2019; 30(4): 155-9. doi: 10.14316/pmp.2019.30.4.155.

Hariyanto AP, Christianti KH, Rubiyanto A, Nasori N, Haekal M, Endarko E. The effect of pattern and infill percentage in 3D Printer for phantom radiation applications. JID. 2022; 23(2): 87-92. doi: 10.19184/jid.v23i2.27256.

Bustillo JPO, Mata JL, Posadas JRD, Inocencio ET, Rosenfeld AB, Lerch ML. Characterization and evaluation methods of fused deposition modeling and stereolithography additive manufacturing for clinical linear accelerator photon and electron radiotherapy applications. Phys Med. 2025; 130:104904. doi: 10.1016/j.ejmp.2025.104904.