Future of orthopaedic in bone defect by using 3D-printed personalized implants: A systematic review

Main Article Content

Abstract

Background: Definitive management and treatment of bone defects caused trauma, infection, inflammation or tumour are still challenging problems in orthopaedics. Three-dimensional (3D) printing is a development strategy that is currently being widely discussed to overcome this problem. This technology has dramatically improved teaching and advanced patient care by giving innovative tools for challenging clinical conditions.

Objective: The aim of this study was to conduct in-depth observations and critical analysis of the current state of 3DPIs (3D-printed personalized implants) for bone defects.

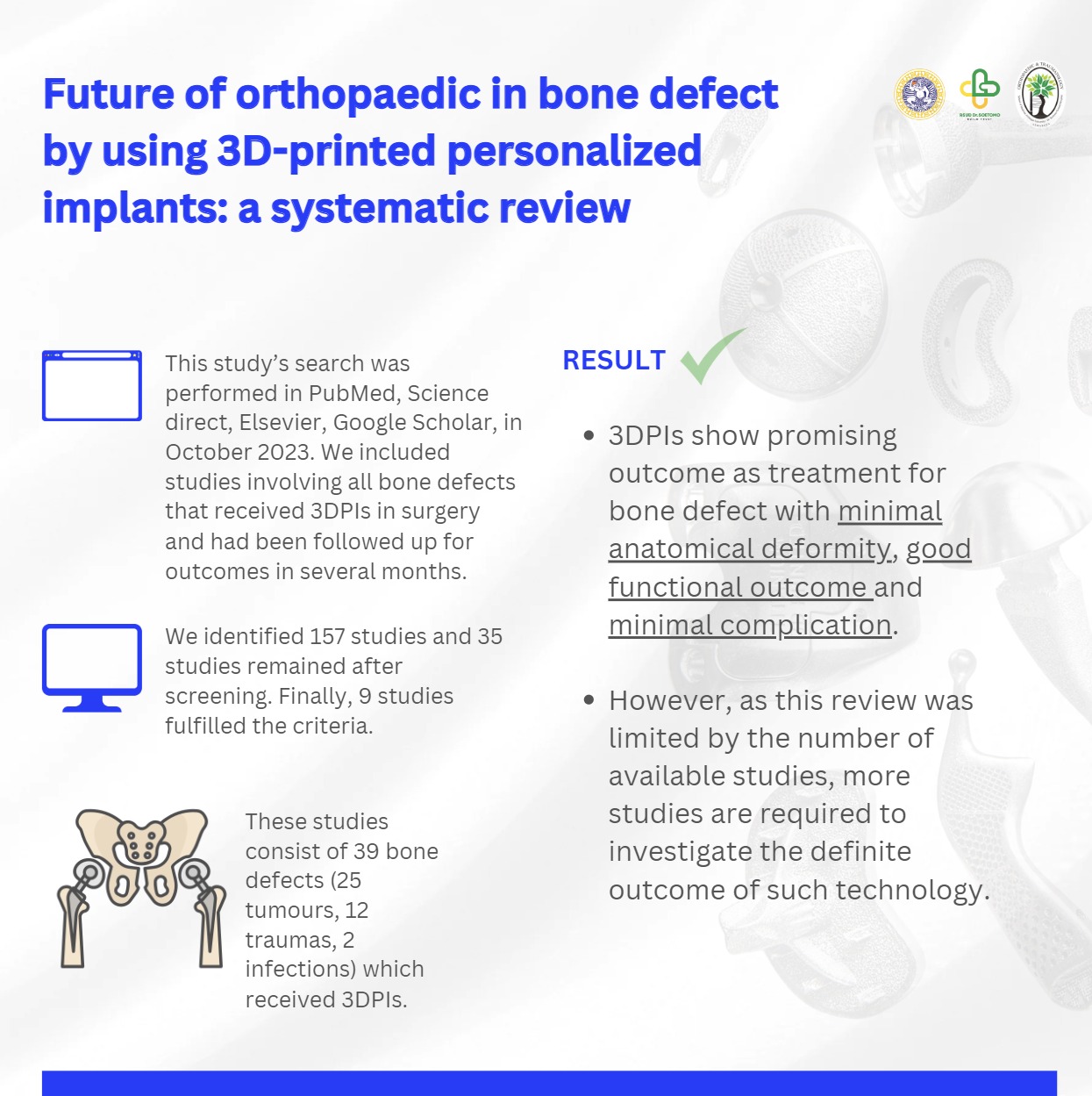

Materials and methods: This study’s search was performed in PubMed, Science direct, Elsevier, Google Scholar, in October 2023. We included studies involving all bone defects that received 3DPIs in surgery and had been followed up for outcomes in several months. There was no date restriction. The recorded outcomes were anatomical outcome, functional outcome, and complication.

Results: We identified 157 studies and 35 studies remained after screening. Finally, 9 studies fulfilled the criteria. These studies consist of 39 bone defects (25 tumours, 12 traumas, 2 infections) which received 3DPIs. The result suggested that the patient who received the 3DPIs had an excellent condition including minimal anatomical deformity, good functional outcome after several months evaluation (between 6 and 24 months) and minimal complication.

Conclusion: 3DPIs show promising outcome as treatment for bone defect with minimal anatomical deformity, good functional outcome and minimal complication. However, as this review was limited by the number of available studies, more studies are required to investigate the definite outcome of such technology.

Article Details

This work is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Personal views expressed by the contributors in their articles are not necessarily those of the Journal of Associated Medical Sciences, Faculty of Associated Medical Sciences, Chiang Mai University.

References

Ferreira N, Sabharwal S, Hosny GA, Sharma H, Johari A, Nandalan VP, et al. Limb reconstruction in a resourcelimited environment. SICOT-J. 2021; 7: 66. doi: 10.1051/sicotj/2021066.

Fu J, Xiang Y, Ni M, Qu X, Zhou Y, Hao L, et al. In vivo reconstruction of the acetabular bone defect by the individualized three-dimensional printed porous augment in a swine model. Biomed Res Int. 2020; 30: 2020. doi: 10.1155/2020/4542302.

Adams S, Dekker T, Steele J, Hamid K. The use of patient-specific 3D printed titanium implants for complex foot and ankle limb salvage, deformity correction, and arthrodesis procedures. Foot Ankle Orthop. 2017; 2(3): 2473011417S0000. doi: 10.1177/2473011417S000018

Zhakeyev A, Wang P, Zhang L, Shu W, Wang H, Xuan J. Additive manufacturing: Unlocking the evolution of energy materials. Adv Sci (Weinh). 2017; (10): 1700187. doi: 10.1002/advs.201700187.

Murr DrLE. 3D Printing: Opportunities, Challenges, and Policy Implications of Additive Manufacturing. Government Accountability Office. 2015; GAO-15-505(June).

Wang J, Yin B, Liu G, Li S, Zhang X, Hu Z, et al. Microhardness distribution of the tibial diaphysis and test site selection for reference point indentation technique. Medicine (United States). 2019; 98(29): e16523.. doi: 10.1097/MD.0000000000016523.

Safali S, Berk T, Makelov B, Acar MA, Gueorguiev B, Pape HC. The possibilities of personalized 3D printed implants—A case series study. Medicina. 2023; 59(2): 249. doi: 10.3390/medicina59020249.

Lin J, Ge J, Gong J, Hong H, Jiang C. Application of digital orthopedic technology in orthopedic trauma. Comput Math Methods Med. 2022; 2022: 3157107. doi: 10.1155/2022/3157107.

Li Z, Lu M, Li M, Luo Y, Tu C. Treatment of pelvic giant cell tumor by wide resection with patient-specific bone-cutting guide and reconstruction with 3D-printed personalized implant. J Orthop Surg Res. 2023; 18(1): 648. doi: 10.1186/s13018-023-04142-4.

Luenam S, Kosiyatrakul A, Phakdeewisetkul K, Puncreobutr C. The patient-specific implant created with 3D printing technology in treatment of a severe open distal humerus fracture with complete loss of the lateral column. J Orthop Surg (Hong Kong). 2020; 28(3): 2309499020960251. doi: 10.1177/2309499020960251.

Tang K, Day W, Tarpada S, Kahn MD. Treatment of an infected tibial shaft non-union using a novel 3Dprinted titanium mesh cage: A case report. Cureus. 2023; 15(1): e34212. doi: 10.7759/cureus.34212.

Kadakia RJ, Wixted CM, Allen NB, Hanselman AE, Adams SB. Clinical applications of custom 3D printed implants in complex lower extremity reconstruction. 3D Print Med. 2020; 6(1): 29. doi: 10.1186/s41205-020-00083-4.

Benady A, Gortzak Y, Sofer S, Ran Y, Rumack N, Elias A, et al. Internal hemipelvectomy for primary bone sarcomas using intraoperative patient specific instruments- the next step in limb salvage concept. BMC Musculoskelet Disord. 2022; 23(1): 1012. doi: 10.1186/S12891-022-05918-1.

Mendonça CJA, Guimarães RM da R, Pontim CE, Gasoto SC, Setti JAP, Soni JF, et al. An overview of 3D anatomical model printing in orthopedic trauma surgery. J Multidiscip Healthc. 2023; 16: 875-87. doi: 10.2147/JMDH.S386406.

Gürkan D, Sagbas B, Dalbayrak B. Investigating mechanical and biological properties of additive manufactured Ti6Al4V lattice structures for orthopedic implants. J Mater Res. 2023; 38(2): 507-18. doi: 10.1557/s43578-022-00837-2.

Bari K. Design, simulation, and mechanical testing of 3D-printed titanium lattice structures. J Composites Sci. 2023; 7(1): 32. doi: 10.3390/jcs7010032.

Rüger M, Seitz AM, Nuss K, von Rechenberg B, Seitz D, Kostmann C, et al. A bioinspired orthopedic biomaterial with tunable mechanical properties based on sintered titanium fibers. Adv Healthc Mater. 2023; 12(2): e2202106 doi: 10.1002/adhm.202202106.

Zumofen L, Kopanska KS, Bono E, Kirchheim A, De Haller EB, Graf-Hausner U. Properties of additivemanufactured open porous titanium structures for patient-specific load-bearing implants. Front Mech Eng. 2022; 7. doi: 10.3389/fmech.2021.830126.

Wang C, Wang Y, Bao Z, Dong J, Geng Y, Liu S, et al. Characterization of microstructure and mechanical properties of titanium -based bioactive ceramics laser-deposited on titanium alloy. Ceram Int. 2022; 48(19): doi: 10.1016/j.ceramint.2022.06.182

Wixted CM, Peterson JR, Kadakia RJ, Adams SB. Three-dimensional Printing in Orthopaedic Surgery: Current Applications and Future Developments. J Am Acad Orthop Surg Glob Res Rev. 2021;5(4):e20.00230- 11. doi: 10.5435/JAAOSGlobal-D-20-00230.

Sun J, Tan SE, Sevao J. The utility of 3D printing for preoperative creation of patient-specific implants for shoulder arthrodesis. Orthopaedic Proceedings. 2023; 105-B(SUPP_2). doi: 10.1302/1358-992x.2023.2.109.

McLaughlin WM, Donnelley CA, Yu K, Gillinov SM, Tuason DA. Three-dimensional printing versus freehand surgical techniques in the surgical management of adolescent idiopathic spinal deformity. J Spine Surg. 2022; 8(2): 234-41. doi: 10.21037/jss-22-28.

Tack P, Victor J, Gemmel P, Annemans L. Do custom 3D-printed revision acetabular implants provide enough value to justify the additional costs? The health-economic comparison of a new porous 3D-printed hip implant for revision arthroplasty of Paprosky type 3B acetabular defects and its closest alternative. Orthop Traumatol Surg Res. 2021; 107(1): 102600. doi: 10.1016/j.otsr.2020.03.012.

Frame M, Leach W. DIY 3D printing of custom orthopaedic implants: a proof of concept study. Surg Technol Int. 2014; 24: 314-7.

Ballard DH, Mills P, Duszak R, Weisman JA, Rybicki FJ, Woodard PK. Medical 3D printing cost-savings in orthopedic and maxillofacial surgery: cost analysis of operating room time saved with 3D printed anatomic models and surgical guides. Acad Radiol. 2020; 27(8): 1103-13. doi: 10.1016/j.acra.2019.08.011.

Suryawanshi CM, Gaur B, Singh AK, Soman D, Sagar S, Bhallamudi R, et al. Microstructure and mechanical characterization of direct metal laser sintered Ti-6Al- 4V alloy for orthopedic implant applications. Mater Today Commun. 2023; 35: 105770. doi: 10.1016/j.mtcomm.2023.105770.

Mathew A, Hasan J, Singamneni S, Yarlagadda PKDV. Nanospikes on customized 3D-printed titanium implant surface inhibits bacterial colonization. Adv Eng Mater. 2023; 25(8). doi: 10.1002/adem.202201306.

Danielli F, Ciriello L, La Barbera L, Rodriguez Matas JF, Pennati G. On the need of a scale-dependent material characterization to describe the mechanical behavior of 3D printed Ti6Al4V custom prostheses using finite

element models. J Mech Behav Biomed Mater. 2023; 140: 105707. doi: 10.1016/j.jmbbm.2023.105707.

Wang Q, Telha W, Wu Y, Abotaleb B, Jiang N, Zhu S. Evaluation of the properties of 3D-printed Ti alloy plates: in vivo and in vitro comparative experimental study. J Clin Med. 2023; 12(2): 444. doi: 10.3390/jcm12020444.